Lenze as the standard solution

The company’s expertise in automation is growing enormously and enjoys widespread respect. The engineering know-how, the reorganized sales division and the scalable, well-balanced product range are Lenze’s strengths. They also make it possible to cooperate with major customers. More than 1,000 machine concepts are being implemented every year. Lenze accompanies its customers as a partner through the whole process of machine development, from the initial idea to the sale. Lenze is one of the few companies to provide central motion control via the PLC (controller-based) and decentralized (drive-based) control on the motor itself.

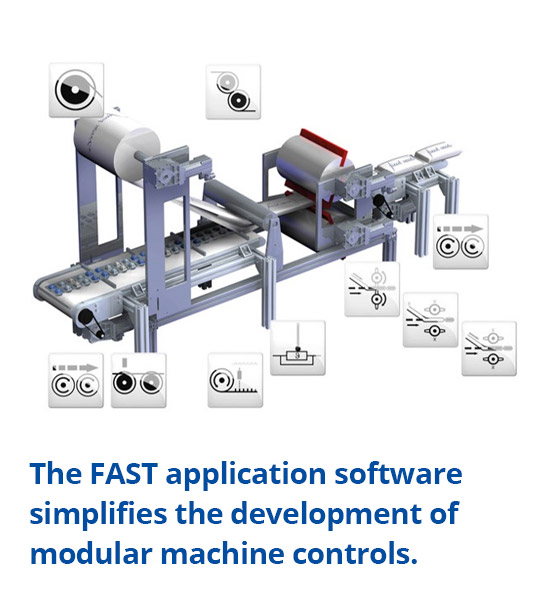

Software-based machine control is becoming increasingly important for machine manufacturers because it reduces the amount of programming they have to do. Lenze offers intelligent software modules for modular machine control. Lenze FAST software, for example, consists of prefabricated, pretested function and technology modules that enable the operator to program the control software easily – in many cases, they only need to adjust the parameters. The modular system makes it uncomplicated to create a standard architecture, which frees up resources for the customer to develop his own special solutions.

The digital twin is what provides the basis for continuous engineering through the entire lifecycle of a machine. It provides data for the commissioning, maintenance or management of a machine. In order to make full use of its benefits, Lenze cooperates with component suppliers, machine manufacturers, and plant operators.

Also, Lenze plays an active part on the board of the Industrial Digital Twin Association (IDTA), founded in 2021. Lenze sees itself as playing a key role here: “We want to set the pace in global factory automation and to be at the forefront of helping to shape the digital transformation,” says Chief Executive Officer Christian Wendler.