The Alquist Winder innovation

Stahlkontor Weser trades in “finished and semi-finished products made of iron and steel; raw materials; and technical articles for mining, industry, agriculture and construction”.

Hans Lenze makes a promise to his customers: “All the gearboxes … are thoroughly checked by us and, where necessary, reconditioned in our own workshop.” In addition to sales, he offers customers advice as well: “Our engineers will be happy to advise any customer on the appropriate way to use the gearboxes.”

In the uncertain years leading to Germany’s currency reform in 1948, he takes every opportunity to procure goods and find customers. In addition to gearboxes, Stahlkontor also sells valves for gas, water and steam, rolling bearings, clutches, electric motors and generators.

But Hans Lente wants to progress from trading to manufacturing: “We should really try to get involved in industry. But only if we can manufacture a product that promises success from the very beginning.” But which product?

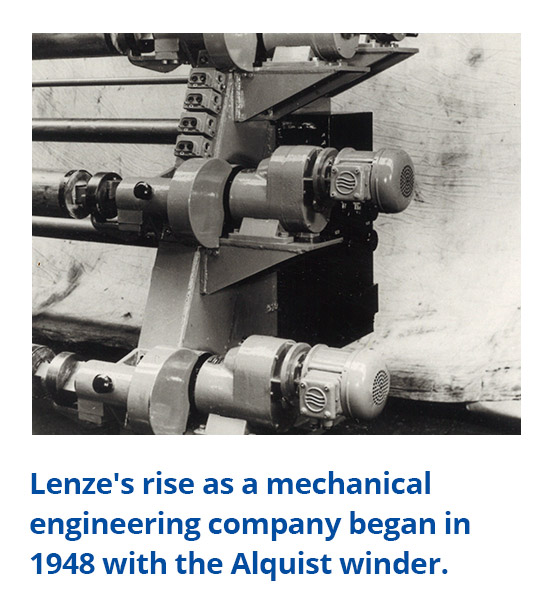

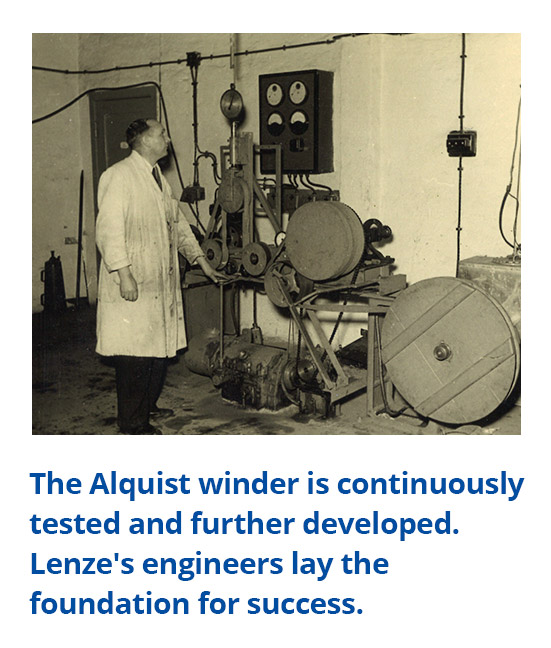

In 1948, Lenze sees a newspaper advertisement for something called the Alquist Winder by Swiss engineer Heinrich Grünbaum. Grünbaum himself says that he named the winder after his Swedish wife. As the owner of the Alquist engineering firm in Berlin, he had developed the innovative three-phase motor in the 1930s. The motor enables the infinitely adjustable winding of webs made of plastic, textile, cellophane, paper or man-made fibers. Thanks to the special design of the armature, it adapts its speed to the torque during winding and unwinding, so that the tension remains constant even when the bale of material becomes thicker or thinner during winding and the speed changes as a result. As the bale becomes thicker, the motor automatically slows down. This avoids tension and tearing.

The versatile Alquist Winder is a genuine innovation for the market. Hans Lenze acquires the license for exclusive production and sells the machine mainly to the textile industry, which is booming in post-war Germany.

The Alquist Winder is manufactured from 1950 onwards, initially in Hamelin and then in rented workshops in Gross Berkel, and it makes Lenze the leading supplier of winding machines. By 1957, sales of winders have climbed to 3.1 million deutschmarks.