Entering the market for electronic drive technology

Lenze continues to develop the Alquist Winder because there are ever more materials that need winding. Nevertheless, the sales figures stagnate in the 1960s. Something fundamental has to change, obviously. As early as 1957, as a kind of alternative to the Alquist Winder, the Stahlkontor has added the so-called Hyberbola Winder, System Dr. Langweiler, to its range, from the Dülken-based company Tonmetall. The centerpiece of this device is not a self-regulating DC motor, but a special electrical control device that automatically regulates the motor output during the winding, in order to adapt the torque to the winding diameter.

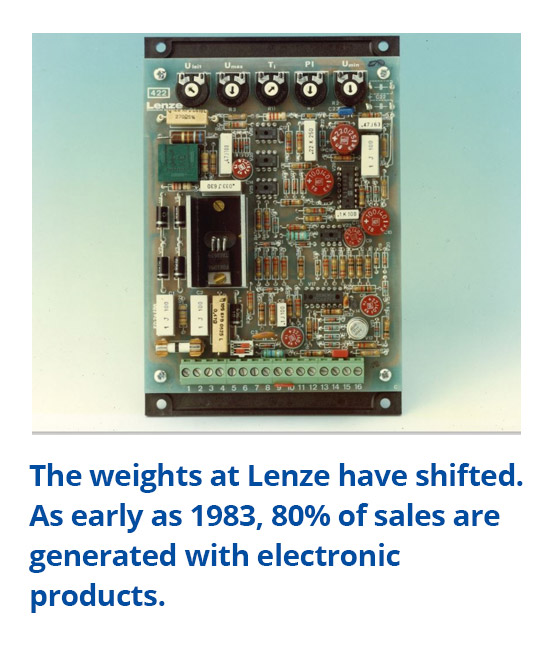

At the end of the 1960s, to become independent of suppliers and to improve its own winding systems, Lenze develops its own control unit for DC drives. To the company’s surprise, the new device achieves outstanding sales, even without a connection to a winding system and despite strong competition from companies such as AEG or BBC. In 1970, Lenze begins series production of the device.

In 1972, through a joint venture with the Japanese company Miki, Lenze gains access to producers of semiconductors in Japan and Southeast Asia. With the help of semiconductor valves called thyristors, Lenze builds ever smaller and ever more reliable control units. Now, the start-up and speed behavior of motors can be controlled with mathematical precision.

Despite this success, Lenze remains skeptical: “Electronics is a very expensive business,” remarks the Family Board. “Will it make a profit?” The sales companies, too, see “only a vast amount of work and not much revenue”.

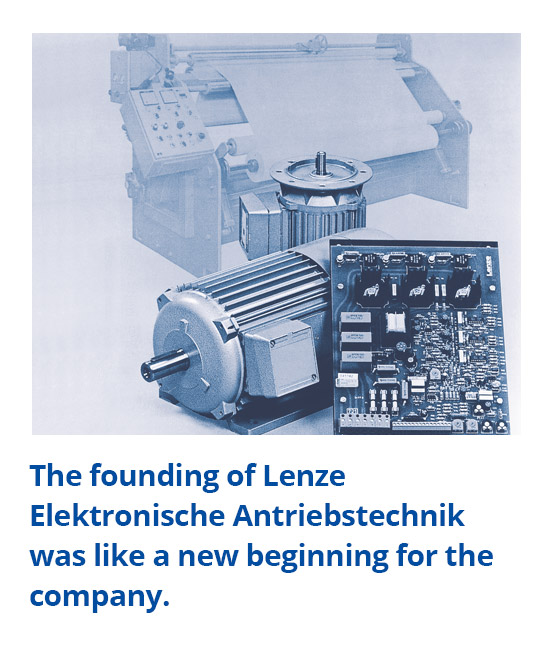

But Alfred Belling believes in electronics. In 1973 he founds Lenze Elektronische Antriebstechnik in 1974 he launches a series of DC speed controllers up to 7.5 kW for straight drives and central winders, which are successfully used in conveyor systems or in paper and textile machines.

In 1976/77, Lenze succeeds in developing a ground-breaking frequency inverter for three-phase AC motors, which greatly simplifies speed control in machine manufacturing.

The further development of frequency inverters gives Lenze a leading position globally. The company now turns its attention to systems engineering and the construction of control cabinets.

With 1,100 employees and yearly revenue totaling 120 million deutschmarks, Lenze is in an excellent position at the end of the 1970s. Its technical advances and, in particular, its entry into the electronic drive technology market have strengthened the company’s position.